We offer you hops from organic farming

Our organic hopsOur Expertise

Selection

The technical team at the Cooperative is responsible for managing varietal selection projects. The team coordinates the different stakeholders that are responsible for developing new hop varieties. It also actively participates in the selection of new hop varieties

Production

Each hop grower is independent and manages his or her own production, but the Technical Services team of the Cooperative is available to advise the growers throughout the growing season.

The team guides the growers in line with the feedback and needs of brewers. It provides technical advice that helps the growers to improve both the quality and the economic yield of their production. As the climate evolves, the team alerts farmers about plant health risks, and distributes advice about pest control management. It also monitors the soil health of the plots of land in order to maintain a superior level of hop quality.

The Technical Services team at the Cooperative is always monitoring technology developments. One of its principle missions is to promote environmentally sound practices. As a Technical Institute, the Comptoir Agricole works hard to develop methods such as monitoring the weather closely so that chemical product use is minimized, and other practices such as thermal defoliation.

Assembly

Quality above all

The COMPTOIR AGRICOLE emphasizes quality assurance throughout the production process. Full traceability is applied from the field to the end of the sales process.

The harvest is carried out with great care.

Hops are harvested and dried at the farm following strict procedures, and are packed on site.

|

|

| Harvesting | Drying the hops |

Each grower delivers his or her own production, which then undergoes stringent checks. The quality of the production will determine the price that each grower gets, according to the following standards:

- Varietal Purity : European regulatory requirements

- Humidity level : European regulatory requirements

- Absence of impurities : European regulatory requirements and Cooperative standards

- Absence of diseases : Cooperative standards

- Drying quality : Cooperative standards

- Color : Cooperative standards

The Comptoir Agricole has its own in-house laboratory where hops are tested for Alpha acid content, humidity levels and nitrate concentration levels.

Storage

5 500 m² (59 200 sq. ft.) of refrigerated halls at - 5°C (23°F).

All the hops production in Alsace must be stored in refrigerated storage within 3 weeks of the harvest. This particular specification dramatically reduces the risk of oxidation of the hops. The refrigerated storage also guarantees a level of freshness for the brewers.

Conversion

The Comptoir Agricole manages the conversion of fresh dried hops into different finished product forms that meet the requirements of each brewer. This permits us to hold the majority of our varieties in the most commonly requested finished product formats, such as:

- Type 90 Pellets

- Type 45 Pellets

- Co2 Extracts

- Hop aroma extracts and other post fermentation products.

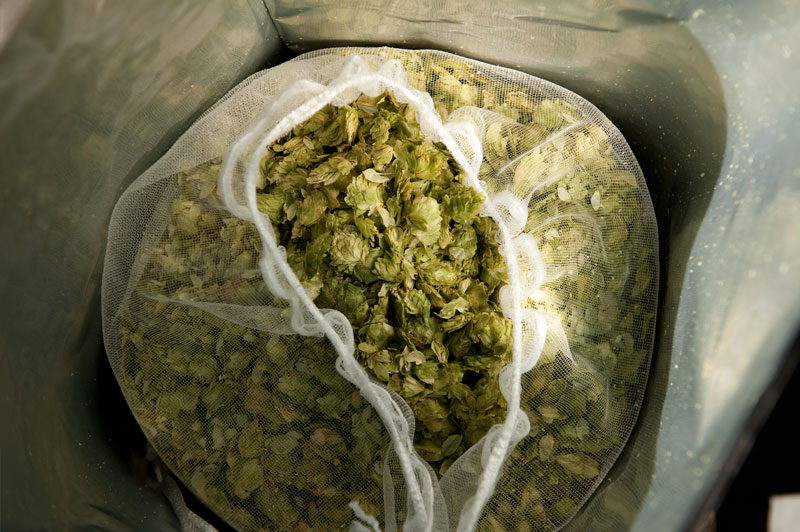

The Comptoir Agricole offers a finished product that is used in dry hopping: the Brew Net. The Brew Net is a food grade polyethylene (PE) net contains between 2 to 4 kilos (4.4 to 8.8 lbs.) of hop cones. The net is packed in a sealed aluminum sachet in which the oxygen is replaced by inert gas. This reduces the risk of oxygenation and preserves the aromatic properties of the hops.

Sales

Hops from the Alsace region grace a number of different beers across the world. Today, almost half of the regional production is sold outside Europe, particularly in North America. Our network of growers is able to adapt to the specification of all brewers. We promote and encourage "sampling": we invite brewers to visit us, and to select their specific hops lots based on on-site sampling.